Methods

Indonesian coffee which has a special unique taste.

Together with the farmers, we take care of coffee from planting, harvesting care to the post-harvest process. Bepahkupi educates farmers to produce quality coffee.

Harvest

Bepahkupi works with educated farmers coffee charries.

Picked coffee is coffee that has been fully ripe and red in color. The characteristics of a coffee are judged by the level of maturity.

The first is green and yellowish green, fruit like this is advised not to picked, the three full red colors indicate that the coffee is perfectly ripe, coffee fruit like this are the best and best coffee fruit to pick and the fourth is dark red, this color indicates that the coffee is too ripe, this color indicates that coffee must be picked immediately.

Sortation of coffee fruit

Coffee fruit are sorted based on quality.

Good coffee fruit is coffee fruit avoid dirt, deformed fruit and diseased fruit of this separation serves to determine the quality grade of coffee quality.

Peeling red fruit skin

The peeling of the coffee skin is done manually and with machine power, however the recommended peeling of the coffee skin is vigorous stripping machine, during stripping flow water continuously into the pulping machine.

Water drain function to soften the fruit skin tissue so that it is easily removed from the seeds.

The result of the peeling process is that the coffee beans still have skin horn or also called HS coffee bean.

Fermentation of coffee seeds

Coffee fruit are sorted based on quality.

Good coffee fruit is coffee fruit avoid dirt, deformed fruit and diseased fruit of this separation serves to determine the quality grade of coffee quality.

Drying coffee seeds

At this stage the results of the fermentation of the cleaned coffee beans are then dried drying can be done by drying manually or using a machine drying.

For drying, sprinkle HS coffee beans evenly on the thick drying floor the stack of coffee beans should be no more than 4 cm, turn the coffee beans regularly, especially when still in a wet state.

Drying time is around 2 – 3 weeks.

Sortation and drying of seeds

After the coffee cherries are peeled, we perform sorting to separate the desired product with the rest of the fruit skin, horn skin, broken coffee beans and other impurities.

Coffee beans will be stable if water content is 12%. Bepah Coffee always supervises this separation / sorting process to maintain quality of coffee produced.

Peeling off the skin of the mark

After the HS coffee beans reach a moisture content of 12%, peel off the horn skin that covers the beans. Stripping can be ground or with the aid of a huller.

Recommended by machine for reduce the risk of damage to coffee beans. The result of stripping at this stage is called rice coffee beans (green bean).

Packaging and storage

Bepah Coffee pack coffee beans in clean sacks and away from odors.

To storage for a long time, the stack of coffee sacks is on a wooden pallet 10 cm thick, and have a gap between the pile of sacks and the wall of the warehouse.

Warehouse humidity always controlled with a humidity range (RH) of 70% in our warehouse.

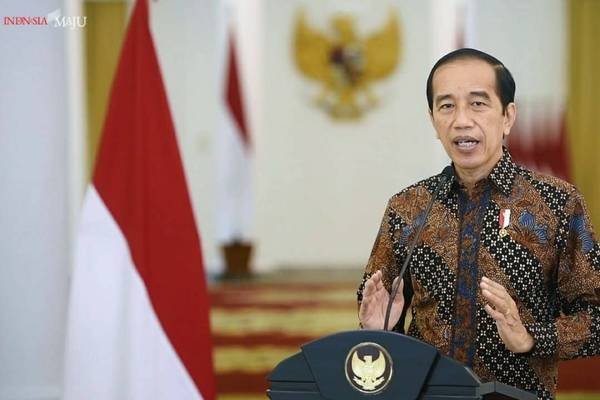

Fully Supported by Indonesian Government

Bepahkupi CEO Inaugurated as Millennial Farmer Ambassador. As an Ambassador for Millennial Farmers carries out several special tasks, both from the President and the Minister of Agriculture.

Based on President Jokowi's direction, the Millennial Farmer Ambassadors are expected to become ambassadors and make young people more interested in the agricultural sector—especially considering the age of most farmers, who are currently around 45 years old and above.

With the participation of young people in this sector, it is hoped that it will strengthen Indonesia's food security in the future. Minister of Agriculture Yasin Limpo also hopes that the Millennial Farmer Ambassadors can become role models as well as business partners for farmers by providing technological innovations to increase quality harvests.

Ministry of Agriculture Republic Indonesia as Bepah Coffee Advisor

Why Choose Us

We are happy to provide you with the best quality arabica and robusta coffee green beans that you can depend on

Serve Best Quality

We oversee the packing, processing, drying process to the process of presenting the product. This makes Bepah Coffee products have a guaranteed aroma, taste, and quality, also supported by latest technology.

Bepah Coffee is flimmer of hope for coffee farmers, so that the farmer's economy will improve. Finally we able to meet the needs of global market with guaranteed quality.

Ensuring Fair Trade for Coffee Farmer

Bepah Coffee plays a role in ensuring development of processing so that there no monopolistic practices that agriculture still uses to harm farmers.

By cutting middleman and improving supply chain, the distribution of coffee will be more efficient and effective so farmer's products are directly linked to the market.

Provide & Customized your Coffee Bean Stock Needs

Bepah Coffee provides raw materials, started from Aceh Gayo where coffee plantations in this land have been developed since 1908, coffee flourishes in Bener Meriah Regency, Central Aceh and a small part of Gayo Lues regions.

Right now, the availablity of coffee raw materials has wide-range coffee variance, also categorized by quality and characteristics that can be customized with our Coffee Experts.

Provide & Customized your Coffee Bean Stock Needs

Bepah Coffee provides raw materials, started from Aceh Gayo where coffee plantations in this land have been developed since 1908, coffee flourishes in Bener Meriah Regency, Central Aceh and a small part of Gayo Lues regions.

Right now, the availablity of coffee raw materials has wide-range coffee variance, also categorized by quality and characteristics that can be customized with our Coffee Experts.

International Market

Established partnership & exports to International Market.

We already expand our services into America, Australia, East Asia & Europe and helping businesses to thrive in coffee industry

● Trusted International B2B Coffee Exporter

● Expertise in Green Coffee Beans with Varies Grade and Characteristics

● Eligible for Exports to International Market

● Supported by Indonesian Government

Partnership with Bepah Coffee

We provide a free and no - obligation initial consultation.

We will help you

understand the details and requirements for your next ventures.

Reach out to us and step up your business with ease.